- Company address

- WeChat

- Hotline:+86-476-5314467

- 中文

With Linxi County, Chifeng City, Inner Mongolia as the center, HengGuangDa plans to build a demonstration base for planting Chinese medicinal materials. It mainly adopts the cooperation mode of "company + base + cooperative (peasant household)", imitating the technology of wild dryland autumn planting, and takes the improvement of dryland income as the main focus. Through technical services, experiments and demonstrations, the company actively guides peasant households to adjust the industrial structure.

While promoting the development of local dryland agriculture, it also provides enterprises with high-quality, safe and reliable medicinal materials. At present, the company has built a core demonstration base for the cultivation of Chinese medicinal materials covering 30,000 mu, mainly including Mongolian astragalus, Scutellaria baicalensis, red peony root, Radix Sophorae, and Radix Gentiana.

The factory is located in Linxi County Industrial Park, covering an area of 150 mu with a construction area of 40,000 square meters, including 7,200 square meters of traditional Chinese medicine repository and 8,572 square meters of traditional Chinese medicine production and processing workshop. The company has Chinese medicine yinpian and Chinese medicine extraction deep processing automatic production line.

TCM decoction piece processing:

In the field of Chinese medicine decoction piece processing, the company has advanced Chinese medicine purification, cutting, stir-frying, moxibustion, carbon production, steaming, boiling, stewing, simmer integrated unit equipment, in order to ensure the traditional technology while achieving automatic continuous production. The annual output is 1500 tons, which greatly improves the production efficiency.

Deep processing of Chinese Medicine extraction:

The company has the most advanced equipment for multistage continuous countercurrent extraction and vacuum belt drying of Traditional Chinese medicine in China. It processes 600 tons of plant extract annually and has the following advantages compared with traditional equipment:

1. Full automatic control;

2. Realize large-scale continuous production;

3. Low amount of solvent extraction;

4. Low extraction and drying temperature;

5. The active ingredients of Traditional Chinese medicine are retained to the greatest extent.

On the basis of inheriting traditional Chinese medicine culture, HengGuangDa company combines traditional technology with modern technology to retain the essence of Traditional Chinese medicine to the greatest extent, and greatly improves the output and quality of products.

HengGuangDa has a rigorous scientific quality management system, from the Chinese medicine planting, processing, production, sales of the whole life cycle of strict control, to ensure the quality of products. Quality control of all products can be traced back to the whole process.

1. Source control

In order to achieve the end product control and stability, the company controls the quality of Chinese medicinal materialsl. The company is now building its own provenance base and standardizing the management of seed treatment, seedling raising, transplanting, field management and harvest. Every link is recorded in detail and the whole process can be traced back.

2. Process control

The company has established a complete quality system based on the drug production quality management standard. Clear the job responsibilities of each post, so that each employee to perform their duties. The quality control Department inspects all raw and auxiliary materials, packaging materials and intermediate products to ensure that the raw materials are qualified. The quality control Department monitors the whole process of drug production. Each link of the processing process fully implements GMP standard to provide assurance for meeting quality requirements.

3. Product release control

The company implements the quality authorizer management system and is fully responsible for drug quality and finished product release. The release of the final finished product shall be subject to the inspection by the Quality Control Department according to the relevant requirements of The Chinese pharmacopoeia or enterprise standards, and the raw material and all links of the processing shall be reviewed and approved by the quality authorized person before release.

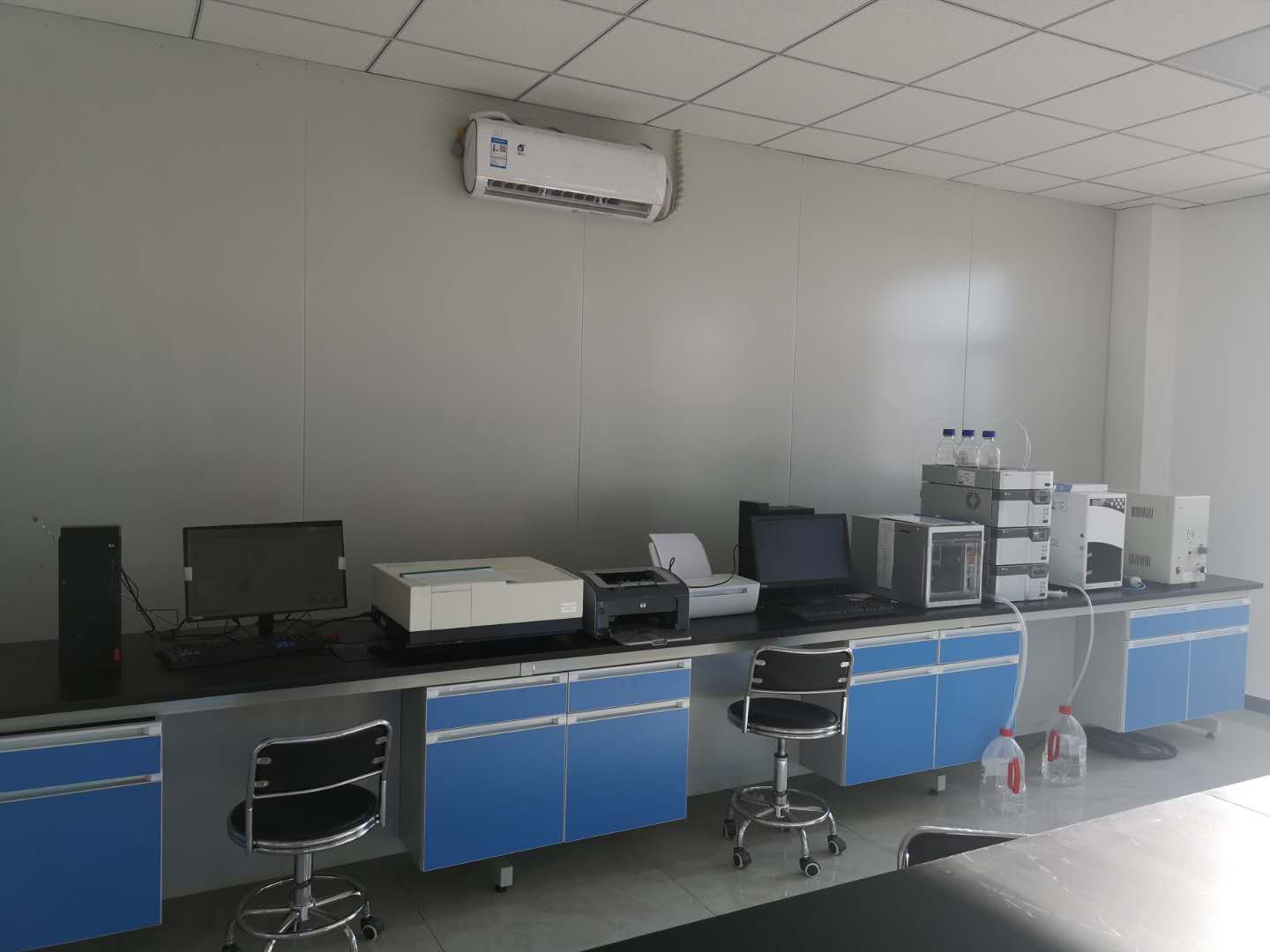

The company has 5000 square meters of R&D center. We have purchased advanced laboratory instruments and equipment at home and abroad, including high performance liquid chromatograph, atomic absorption spectrophotometer, gas chromatograph and other precision instruments. The R&D center is equipped with more than 20 functional rooms, such as physical and chemical laboratory, chromatographic room and microbial detection room, with excellent environment and domestic first-class level of Traditional Chinese medicine detection laboratory.

At present, the company has 37 technicians, including 3 senior engineers, 1 doctor and 4 masters. Through the combination of production, study and research, going out, bringing in and other different ways, the company has cultivated its own professional talents and created a professional, efficient and cohesive talent team.

Company laboratory equipped with advanced instruments and equipment at home and abroad, has the domestic first-class research and development of traditional Chinese medicine (TCM) detection level. The company has established a r&d platform for TCM planting and processing technology, and established good industry-university-research cooperation relations with Inner Mongolia Medical University, Beijing University of Chinese Medicine, Institute of Medicinal Plants, Chinese Academy of Medical Sciences and other institutions.

The company's current r&d projects:

1. Research on wild provenance development and domestication of medicinal materials;

2. Study on the standardized ecological planting of astragalus root, Red peony root and Daphne root;

3. Research on the development and utilization of by-products of Astragalus, including the development and utilization of Selenium-rich astragalus and Astragalus flower, and the development and utilization of drug residue;

4. Research and development of TCM planting and deep processing technology and equipment.

At present, the company has applied for 13 patents, including 3 national patents for "a method to improve the germination rate of red peony root and the survival rate of seedlings", and 8 new patents.

Add: Linxi Industrial Park, Chifeng City, Inner Mongolia, China

Tel: +86-476-5314467

Fax: +86-476-5314467

E-mail: HGD04765314467@163.com

Copyright(C)2020,Inner Mongolia Evergrand Pharmaceutical Corp, Ltd. All Rights Reserved. Supported by ChemNet ChinaChemNet Toocle Copyright Notice